With the rapid development of science and technology, laser cutting technology has set off a revolutionary change in the sheet metal processing industry with its high precision, high efficiency and high flexibility. As the core equipment of this technology, laser cutting machine not only greatly improves the production efficiency and product quality of sheet metal processing, but also injects new vitality into the transformation and upgrading of the industry.In combination with these conditions, laser cut machine It can still let us see good development and bring fresh vitality to the whole market. https://www.cnyoniklaser.com/

Innovative application of laser cutting machine in sheet metal processing industry

1. Working principle and advantages of laser cutting machine

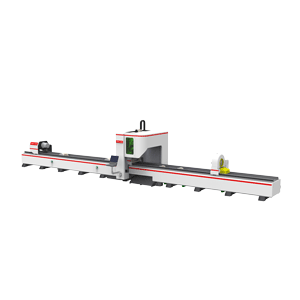

The laser cutting machine irradiates the surface of sheet metal material with a high-energy-density laser beam, causing the material to melt, vaporize or even reach the ignition point quickly, and at the same time uses high-speed airflow to blow away the melted or vaporized material, thereby achieving the purpose of cutting. Compared with traditional mechanical cutting methods, laser cutting machines have significant advantages:

?High precision?: The focusing diameter of the laser beam is extremely small, which can achieve micron-level cutting accuracy and meet the precise processing requirements of complex graphics.

?High efficiency?: The laser cutting speed is extremely fast, especially in the cutting of thin plate materials, its efficiency far exceeds that of traditional cutting methods.

?High flexibility?: Laser cutting machines can easily cut various complex shapes without molds, greatly shortening the product development cycle.

?Small heat-affected zone?: The heat-affected zone of laser cutting is extremely small, which is conducive to maintaining the original performance of the material and reducing subsequent processing procedures.

2. Application of laser cutting machines in sheet metal processing industry

In the sheet metal processing industry, laser cutting machines are widely used in many fields such as automobile manufacturing, aerospace, electronics and electrical appliances, furniture manufacturing, etc. The following are specific application examples:

?Automobile manufacturing?: In the process of automobile manufacturing, laser cutting machines are used to cut body panels, structural parts, etc., which not only improves cutting accuracy, but also reduces material waste.

?Aerospace?: The aerospace field has extremely high requirements for the strength and lightweight of materials. Laser cutting machines can meet these high-precision and high-quality cutting requirements, providing strong support for the manufacture of aerospace vehicles.

?Electronics?: In the electronics and electrical industry, laser cutting machines are used to cut circuit boards, housings and other components. Their high precision and flexibility ensure the fineness and reliability of the products.

?Furniture manufacturing?: In furniture manufacturing, laser cutting machines can quickly cut plates of various shapes, improve production efficiency, reduce manual operations, and reduce production costs.

3. Future development trends of laser cutting machines

With the advancement of intelligent manufacturing and Industry 4.0, the application of laser cutting machines in the sheet metal processing industry will be more extensive. In the future, laser cutting machines will develop towards higher power, finer cutting quality, and more intelligent operating systems. At the same time, with the continuous emergence of new materials, laser cutting machines will also be continuously upgraded to meet the cutting needs of more types of materials.

In addition, environmental protection and energy saving will become an important trend in the development of laser cutting machines. By optimizing the cutting process and laser source design, reducing energy consumption and emissions, and achieving green production.

4. Conclusion

The innovative application of laser cutting machines in the sheet metal processing industry not only improves production efficiency and reduces costs, but also provides strong support for the transformation and upgrading of the industry. With the continuous advancement of technology and the continuous expansion of application fields, laser cutting machines will play a more important role in the future.

Innovative application of laser cutting machine in sheet metal processing industry

This article conducts an in-depth analysis of the innovative application of laser cutting machines in the sheet metal processing industry, and comprehensively demonstrates the unique charm and broad prospects of laser cutting machines from working principles, application examples to future development trends. I hope this article can provide readers with valuable reference and inspiration.