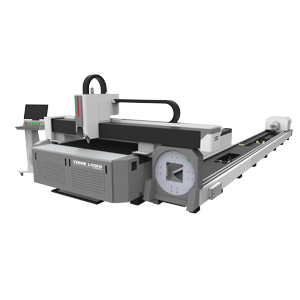

In today’s rapidly developing industrial manufacturing field, efficient and precise processing technology has become the key to improving the competitiveness of enterprises. Among them, the CO2 laser cutting machine has become an indispensable industrial tool for many industries with its unique advantages. This article will explore the working principle, application advantages and wide application of the CO2 laser cutting machine in different fields, aiming to provide readers with a comprehensive and in-depth industry insight.in fact cnc laser cutting machine Our related products were once praised by users, which is the best self-affirmation of the products. https://www.cnyoniklaser.com/

?CO2 laser cutting machine: an industrial tool for efficient cutting?

1. Working principle of CO2 laser cutting machine

The CO2 laser cutting machine mainly uses a high-energy CO2 laser as a light source, and focuses the laser beam into a very small spot through a focusing mirror, thereby forming a high-temperature and high-density energy area on the surface of the processed material. When the laser beam contacts the material, the material will quickly absorb the laser energy and convert it into heat energy, causing the local area to quickly heat up to above the boiling point, thereby realizing the vaporization and cutting of the material. This process has extremely high speed and precision, and can meet the cutting needs of various complex shapes and fine structures.

2. Application advantages of CO2 laser cutting machine

?Efficient cutting?: The CO2 laser cutting machine significantly improves production efficiency with its high-speed cutting speed. Compared with traditional mechanical cutting methods, laser cutting does not require the tool to contact the material, reducing friction and resistance during the cutting process, thereby achieving faster cutting speeds.

?High-precision processing?: Laser cutting has extremely high precision and stability, which can ensure the flatness and smoothness of the cutting edge. This feature gives the CO2 laser cutting machine a unique advantage in the field of precision processing.

?Wide applicability?: The CO2 laser cutting machine is suitable for cutting a variety of materials, including metals, non-metals, composite materials, etc. Its powerful cutting ability makes it widely used in many industries such as automobile manufacturing, aerospace, and electronics.

?Environmental protection and energy saving?: No auxiliary gas or coolant is required during the laser cutting process, which reduces environmental pollution and energy consumption. At the same time, the waste generated by laser cutting is easy to recycle and process, which is in line with the green production concept of modern industry.

3. Application fields of CO2 laser cutting machine

?Automobile manufacturing?: In the automobile manufacturing industry, CO2 laser cutting machines are widely used in the cutting and welding of body panels. Its high-speed and high-precision cutting capabilities enable automobile manufacturers to respond quickly to market changes and improve production efficiency and quality.

?Aerospace?: In the field of aerospace, high-precision processing and lightweight design of materials are crucial. With its excellent cutting performance and stability, CO2 laser cutting machines have become one of the indispensable equipment in aerospace manufacturing.

?Electronic and electrical appliances?: In the electronic and electrical industry, CO2 laser cutting machines are used to cut components such as circuit boards and housings. Its precise cutting ability and ability to handle tiny structures make electronic and electrical products more refined and reliable.

?Advertising logo?: In the advertising logo industry, CO2 laser cutting machines are used to make various exquisite signboards, billboards, etc. Its flexible and diverse cutting methods and high-precision cutting effects make advertising logos more vivid and attractive.

?CO2 laser cutting machine: an industrial tool for efficient cutting?

IV. Suggestions and prospects

With the advent of the era of Industry 4.0, intelligent manufacturing has become the mainstream trend of global industrial development. As an important part of intelligent manufacturing, CO2 laser cutting machines play an increasingly important role in improving production efficiency, reducing costs, and improving product quality. In the future, with the continuous advancement and innovation of laser technology, CO2 laser cutting machines will be applied and promoted in more fields. At the same time, in order to meet the personalized needs of different industries and customers, laser cutting machine manufacturers will continue to develop new cutting technologies and equipment to promote the sustainable development and progress of the laser cutting industry.